Gap filling is at the top of my list of things I’d rather avoid when building. In my case, I always have that 1 gap that requires multiple passes before it’s fixed. So for me, anything to reduce the tedium is welcome. I’m currently using various methods for gaps and I spotted this new product at a local online shop: it’s a putty that dries ‘instantly’ with the help of UV light. The set is not cheap but I figured if it makes my life easier and gap filling faster it’s worth the cost.

The 2 components are sold separately. Naturally you only need to buy the UV light once.

I believe Gemo is Taiwanese brand. Instructions on how to use the putty is printed at the back. Looks straightfoward enough with the only concern really being that you can’t really use this under natural Sunlight.

The UV light comes with a mini-USB charging cable and a strap which isn’t long enough to be able to be looped around the wrist. It’s for hanging purposes only. The putty itself comes in a vacuum sealed bag and the tin has a screw on lid.

The putty is translucent white and looks and feels like a large wad of wax. The surface is somewhat hard although once you break through the surface layer you do get a typical putty-looking glob of wax-like… er… putty.

The UV light has a push button on/off at the back and is listed to have power for 2 hrs of usage. I guess it’ll also come in useful to check for counterfeit currency.

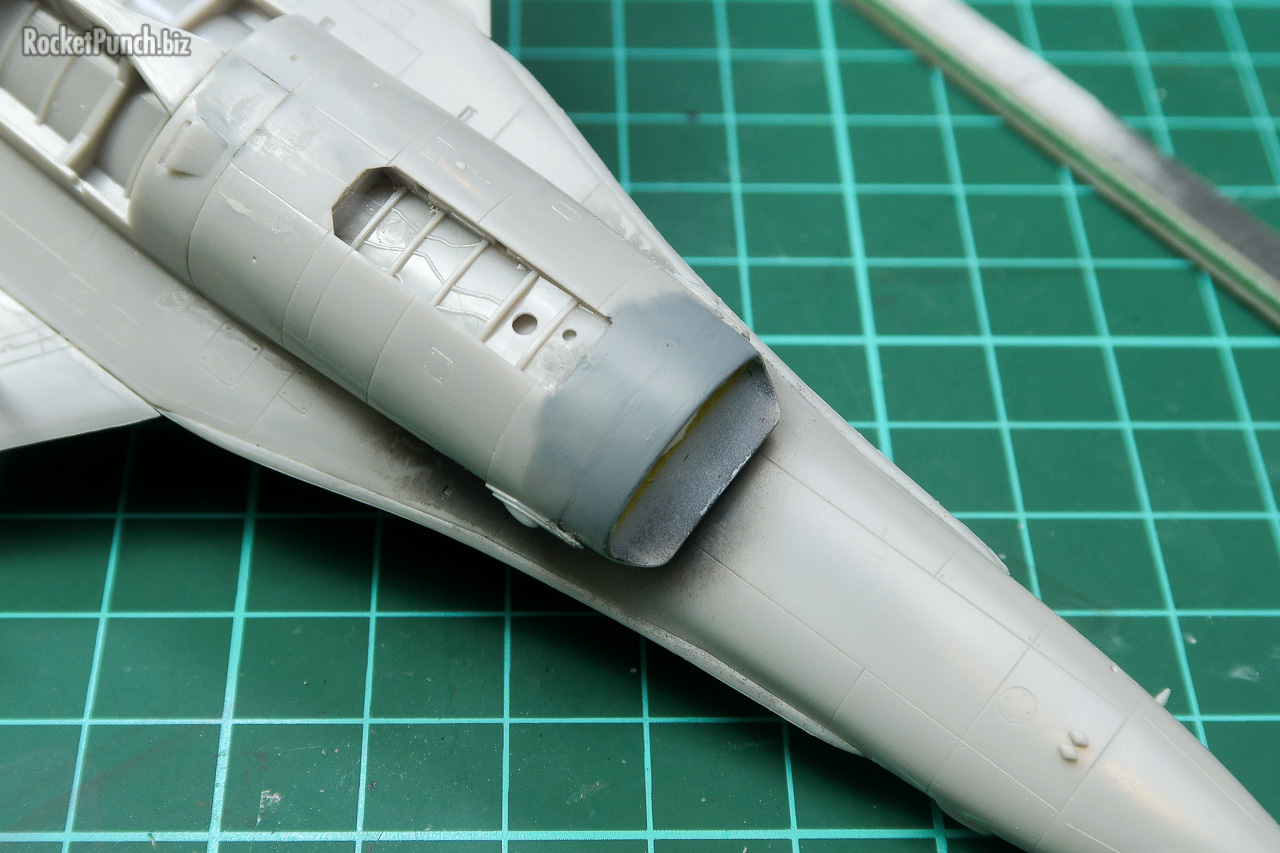

So how well does it work? Time to test it out! First my (not so) excellent workmanship on the test mule.

As mentioned, once you break the harder surface of the putty in the tin, you get this waxy substance which is somewhat soft to the touch. It also washes readily off the hands with water.

So after laying a thin coat over the T-shaped gaps I shone the UV light onto the area. The instructions say, depending on the thickness, to give the area a 5-20 second zap. I just went 20 or so seconds.

It’s immediately dry and hard to the touch. It’s also somewhat transparent, especially since the bare plastic underneath is gray color.

I then sanded the putty smooth which worked better (unsurprisingly) when some water is added to help the process along. To check the result I brushed some medium gray paint on the area. Looks alright I think.

But how well does it take scribing? I went ahead to scribe the panel line, ran some thin cement to ‘smoothen’ the scribed line, then gave it some dark gray wash. I think it looks good. I checked the joint again after 24 hours and found that the putty did not shrink. Nice.

After this I tested to see if the putty will work on vinyl/polycap parts since usual plastic putty doesn’t. The good news is that it does: it stays in place and is still sandable. The bad news is you can’t sand the surrounding area so applying and sanding requires some precise work. At least it works though!

Lastly, I also did a test where I left some putty out in the open in my living room for half a day. In the evening I checked it and found that it had only hardened slightly but was still malleable. So it looks like it’s fine being exposed to a whole day of indirect sunlight.

So, it dries fast, is odorless, sands easily especially when wet, and doesn’t shrink once cured. I do have 2 minor quibbles. Firstly, it’s not cheap. But you get a lot of it for the money. The 45g tin will go a long way. Another is that it dries somewhat transparent and would be better if it had some color to make it more visible. According to their online guide, you can tint the putty with pigment or dye. But why not have it colored in the first place?

In any case, this was only a quick test. The online guide says that you can mix ethanol into it to make a paste for easier application and I’m also curious if it can replace epoxy putty. So longer term tests are needed but my first impressions are quite good so far. Recommended.

~ Review courtesy of my wallet