Kit Info

Kit Info

Manufacturer : AFV Club

Scale : 1/48

Media : Injection Plastic and Photo-etch

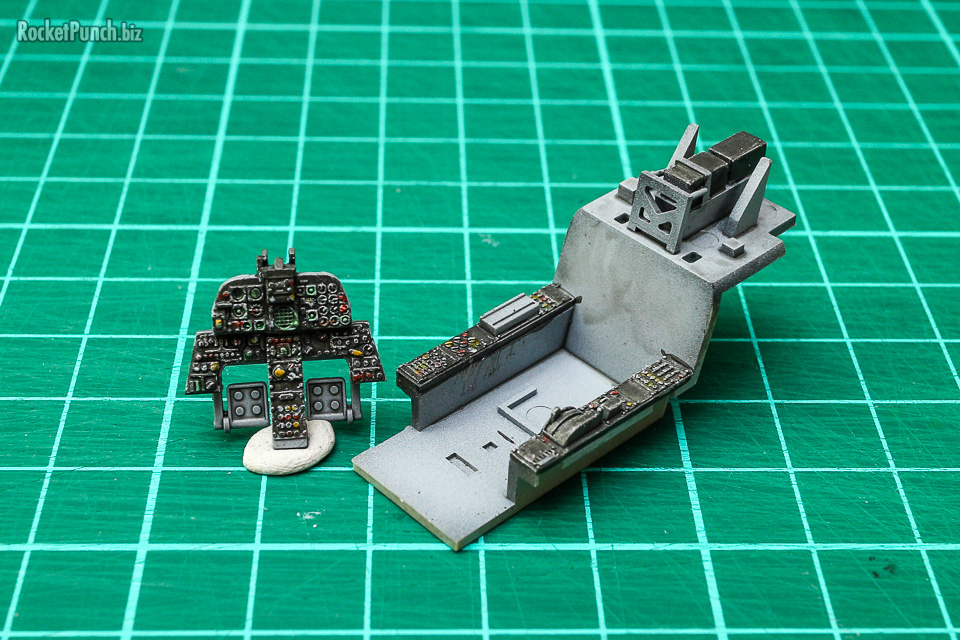

My next kit is a new build (as opposed to another Shelf Queen) of a USAF F-5E Tiger II flown as an Adversary for training purposes. The build begins with the cockpit as usual. Details are nice and are finely raised.

I first sprayed a base coat of Model Air Black Grey then Mig Ammo Dark Compass Ghost Gray.

The instrument panels were first hand painted Black Grey, then I randomly painted Game Color Sun Yellow and Bloody Red to the dials. The center dial was painted Model Color Transparent Green. Everything was given a wash of black-tinted thinned Future. Once that dried I sprayed a flat coat and then dry-brushed all the raised details with a Derwent Metallic Silver pencil. It’s been a while since I’ve done this and I quite like the end result.

I decided to add a resin aftermarket resin seat for this build and below is a comparison of the seat from the kit and the one from Wolfpack Designs. I managed to ping off the very small blade (canopy breaker?) on the tip of the seat so I replaced with one fashioned from plastic plate. I’m surprised the shape is quite different but it’s a lot more detailed.

AFV Club gives the option for an open port gun bay but without the details within. Fitting the 2 panels closed was an exercise in a lot of cutting, trimming and dry fitting. In the end, I cut off some of the locating tabs and added my own with plastic plate.

The fit is not perfect with the bottom section not sitting quite flush on the fuselage and there is a big gap on one side. I masked off the details and carefully trimmed, sanded and buffed down the slight step at the bottom. I tried various means to filling the big gap but ended up using a very small roll of epoxy putty which when cured, will need to be re-scribed.

I usually use Dymo Tape for scribing but am trying out HiQ Parts’ 3mm Carving Guide Tape. The tape conforms to curves much better and is still stiff enough to guide a scriber. I think I can retire my roll of Dymo Tape now.

I used my sewing pin + pin vise to scribe a shallow guide line and then used my 0.15mm chisel to scribe the actual panel line.

There is an injection pin mark inside each intake that needs filling. Normally I would simply ignore these but they are visible when assembled on this one. I used my melted sprue cement solution to fill the holes and left to cure for half a day.

Using a piece of sandpaper taped to a satay stick I’m able to reach this concave area. It was was then sprayed Insignia White over a base of Model Air Black Grey.

There is a big injection pin mark and sprue nub inside the other intake part.

I fixed the injection pin mark inside the intakes as best as I can and sprayed it Model Air Insignia White over Model Air Black Grey. The intakes are quite small and a dry-fit shows my less than perfect work was enough.

This time, I’m a lot more careful with assembly so I did a lot of dry-fitting and checking for gaps before committing with cement. Except for the gun bay door on the nose, fitting is excellent and I think I can avoid using putty in most places.

Construction continues…